2026-02-02

Multiple production lines completed and launched overseas, earning certifications and accolades in the humanoid robotics field

Recently, multiple core production lines, strictly adhering to lean manufacturing principles, have successfully completed their overseas deployment with stable production capacity and excellent product quality. Meanwhile, breakthrough achievements have been made in the humanoid robotics sector, earning authoritative certifications and marking another significant milestone.The successfully completed electronic water pump production line focuses on core demands in the high-end manufacturing sector. Leveraging independently developed process technology systems, it provides efficient and reliable core support for the industry, facilitating performance iteration and quality upgrades for end products.The coordinated implementation of multiple core production lines has successfully concluded before the New Year. This achievement reflects both the concerted efforts of all employees in overcoming challenges and serves as compelling evidence of the company's continuous optimization of its intelligent manufacturing system. To seize the pre-holiday delivery window and ensure orders were fulfilled before the Spring Festival, all staff remained dedicated to their posts. By optimizing production schedules, securing raw material inventories in advance, and streamlining upstream and downstream supply chain coordination, the team sprinted toward pre-holiday delivery targets, achieving a 100% delivery rate to successfully close out the year and welcome the New Year with solid results.Major breakthroughs were also announced in the humanoid robotics sector. Through deep technological cultivation in core components, the company has successfully earned authoritative industry certifications and accolades. Three core categories—ball screws, RV/harmonic reducers, and coreless motors—have simultaneously achieved technological breakthroughs. By optimizing materials and processes, fully automated production lines have been established, efficiently balancing precision and productivity. Material flow is entirely handled by AGV transportation, with manual labor only assisting in material preparation from warehouse to equipment. This enables full-process controllability and traceability, meeting large-scale delivery demands and injecting strong momentum into New Year development.Currently, the company's professional technical and logistics teams are strictly following high-standard industry protocols, systematically carrying out full-process operations including production line dismantling, precision component protection, overall packaging, and final pre-shipment inspections. Production lines bound for overseas have completed standardized, meticulous packaging and stand ready for dispatch. With united efforts and strict attention to detail, all personnel are ensuring that production line equipment, both domestic and international, is delivered safely and smoothly to its destinations for rapid commissioning and operation.The successful completion of these production lines and certification breakthroughs in the humanoid robotics sector represent important practical achievements in the company's deep cultivation of core technologies and strengthening of industrial chain resilience. They also lay a solid foundation for strategic industrial development planning in the coming year. Each production line will fully integrate intelligent management concepts to achieve precise control and efficient coordination throughout the production process, further optimizing capacity layouts for high-end core component manufacturing, enhancing industrial core competitiveness, and providing strong support for the transformation from "Made in China" to "Created in China."

Detail

2026-02-02

Starting Point of the Heart: Warm Currents Initiative – Zhongke Moutong Gathering Love in Zhenping

Detail

2026-01-22

Sowing the Spark of Growth by the Canal: Public Welfare Sharing Helps Youth Build a Bright Future

On December 20, the “In the Name of Love – Canal Imprint Charity Fair” was held at Canal-5 Creative Block. Focusing on youth growth and education, the event brought together tech-company representatives, educators and more than a hundred young people. As a special guest, Zhao Dan, Chairman of Zhongke Motong, shared his personal journey under the theme “Serving the Country through Technology – Youth Taking Responsibility”, and donated RMB 50,000 to the Changzhou Next-Generation Care Fund to support the construction of youth-education practice bases and daily care programs.Using His Own Story to Interpret the Spirit of Striving and Urging Young People to Nurture Patriotic FeelingsAt the sharing session Zhao Dan traced his path from an ordinary student growing up along the canal to the founder of a technology enterprise. “Patriotism must be integrated into daily study and practice,” he stressed. “As a student I kept tackling problems in automation; after graduation I led my team to break bottlenecks in smart equipment for new-energy vehicles. Every choice came from a sense of responsibility for national development.”He offered young people three suggestions: stay curious—curiosity is the engine of exploration; face failure—setbacks are the only road to experience; love learning—learning is the root of every dream. “China’s technology is advancing at lightning speed. You are not only witnesses but also participants. I hope you will contribute your wisdom in key fields and let the world see the power of China’s youth.”Charitable Donation to Support Next-Generation Care, Focusing on All-Round Youth DevelopmentAt the venue Zhao Dan presented a RMB 50,000 cheque to the city’s Next-Generation Care Fund. The money will be used to upgrade youth education-practice bases, buy science-teaching aids and help teenagers from financially strapped families. The head of Changzhou’s Working Committee for the Care of the Next Generation said, “The donation is not only material support but also spiritual encouragement. With these funds we will launch more hands-on tech activities and career-orientation programs to broaden young people’s horizons and help them set lofty goals.”In recent years Changzhou’s committees at all levels have been advancing youth-growth plans, integrating enterprises, schools and communities to build a diversified home-school-society education mechanism. The new donation will further enrich these programs and provide higher-quality support for young people.Opening a Practice Base to Create a “Walking Ideological-Political Classroom”, Empowering Education with TechnologyTo deepen tech education for young people, Zhao Dan opened Zhongke Motong’s smart workshop and technology exhibition hall as a “walking ideological-political classroom”. Staffed by professional instructors, the base offers hands-on courses in industrial-robot operation and digital-line cognition, allowing teenagers to experience the value of technological innovation in an immersive way.“Technology is not just laboratory results; it is a force that drives social progress,” Zhao Dan explained. The base will regularly host student visits and jointly develop science curricula with schools, moving the concept of technological innovation from the textbook into real life.

Detail

2026-01-22

Siemens, Tongji University Sino-German Mechanical Engineering Center, Zhongke Motong 2026 Industrial Embodied Robotics Industry Exchange Conference

On January 20, 2026, the Siemens team and the Sino-German Mechanical Engineering Center of Tongji University visited the headquarters base of Zhongke Motong, successfully holding a specialized negotiation meeting in the field of industrial embodied robotics. Centered on the theme of "technology integration, collaborative empowerment, and win-win development," senior executives and core technical teams from all parties gathered to engage in in-depth discussions on key topics such as the R&D of core technologies for industrial embodied robots, intelligent production line upgrades, industrial chain resource integration, and the expansion of high-end application scenarios. Leveraging their core strengths in respective fields and highly aligned development philosophies, the parties reached a preliminary cooperation intention, laying a solid foundation for building a long-term and stable partnership and jointly exploring the high-end intelligent manufacturing market.Tripartite Empowerment: Building a Solid Foundation for CooperationAt the meeting, the three parties reached a consensus on the global development trends of the industrial embodied robotics industry and the needs of local innovation. As the digital and intelligent transformation of manufacturing enters a critical phase, industrial embodied robots, as core equipment, are evolving toward high precision, flexibility, and AI empowerment. There is an urgent need for industry-academia-research collaboration to overcome technological bottlenecks and industrialization challenges.As a global leader in industrial automation and digitalization, Siemens has built a comprehensive solution system covering the entire value chain of industrial embodied robots, thanks to decades of technological accumulation. Its related technologies have been successfully applied in various fields such as automotive, electronics, and machinery manufacturing, creating significant improvements in production efficiency and cost savings for global customers.The Sino-German Mechanical Engineering Center of Tongji University, relying on the profound foundation of Sino-German cooperation, integrates resources from universities and industries in both countries. It has achieved fruitful results in intelligent robot R&D, localized industrial applications, and digital twin technology, and hosts research platforms such as the Intelligent Robot Center and the Advanced Manufacturing Technology Center.Zhongke Motong has been deeply engaged in the manufacturing of core components for humanoid and industrial embodied robots for many years. With continuous R&D investment and technological breakthroughs, it has achieved efficient mass production and full-process quality traceability of core components, providing solid hardware support for the performance improvement of industrial embodied robots.All three parties agreed that the complementary advantages in scientific research, software, and hardware provide broad space for cooperation.Focusing on the Core: Mapping Out the Path for Tripartite CooperationThis negotiation closely aligned with the common needs and future trends of the industrial embodied robotics industry, clarifying the macro cooperation framework and collaborative direction. The three parties will leverage their respective core strengths to promote the integration and value transformation of technological resources, injecting joint momentum into the high-quality development of the industry. A flexible and efficient collaboration mechanism will be established for long-term development, covering multiple dimensions such as technological innovation, industrial empowerment, and ecological co-construction, forming a mutually beneficial and win-win cooperation pattern.Collaborative Progress: Jointly Drawing the Blueprint for Industrial DevelopmentThe Siemens team stated that this preliminary cooperation intention is an important step in integrating global technological resources with local innovation capabilities. Through in-depth collaboration, it is expected to develop more competitive industrial embodied robot products and solutions, injecting new momentum into the digital transformation of China's manufacturing industry.The Sino-German Mechanical Engineering Center of Tongji University pointed out that, with Sino-German technology integration and industry-academia-research collaboration at its core, Siemens' global technological resources and Zhongke Motong's industrial experience provide an excellent platform for the transformation of scientific research achievements. It is hoped that this cooperation will serve as an opportunity to promote two-way empowerment of technological innovation and talent development in industrial embodied robotics, supporting localized industrial implementation.Mr. Zhao Dan, Chairman of Zhongke Motong (Changzhou) Intelligent Manufacturing Co., Ltd., stated that the cooperation based on complementary advantages of the three parties will inject strong momentum into the company's core technology and intelligent transformation of production lines. Follow-up efforts will aim for rapid breakthroughs in technology R&D and production line upgrades, working with all parties to advance the industrial embodied robotics industry toward high-end development.This meeting established an efficient communication and cooperation bridge for the three parties. It is hoped that this negotiation will serve as a starting point to refine cooperation plans and achieve substantive breakthroughs in areas such as joint R&D of core technologies, digital production line transformation, and collaborative market expansion. Together, they will promote the upgrade of the industrial embodied robotics industry toward high precision, high flexibility, and intelligence, contributing to the advancement of China's manufacturing industry toward high-end development.

Detail

2025-12-22

Focusing on innovation of core components: Zhongke Motong 2025 embodied intelligent humanoid robot scene application ecology annual meeting unleashes technological potential

Embodied intelligence is ushering artificial intelligence into a new era of physical-world interaction. As its most representative carrier, humanoid robots are embracing unprecedented development opportunities. Their human-like form offers natural interaction advantages and environmental adaptability. With breakthroughs in core actuators and sensor technologies—especially the deep empowerment of AI large models in cognition, decision-making, and motion control—the intelligence and practical value of humanoid robots are rapidly advancing, crossing the critical threshold from technical demonstrations to large-scale deployment.From December 3 to 5, Zhongke Motong showcased cutting-edge humanoid robot technologies at the 3rd Embodied Intelligence Humanoid Robot Scenario Application Ecology Annual Conference 2025,demonstrating its strong capabilities at booth R05. Yan Jiaxiang, Executive Dean of the Intelligent Manufacturing Research Institute, delivered a keynote speech, contributing valuable insights to the industry.[Industry Summit] Focusing on New Opportunities for Humanoid Robot Mass ProductionAs a benchmark event in the humanoid robot field,this year’s conference centered on the theme "Embodied Intelligence · Humanoid Evolution · Scenario Breakthrough", aiming to explore how embodied intelligence drives leaps in perception, cognition, decision-making, and control of humanoid robots. It showcased cutting-edge applications and real-world implementations in industrial, service, and special-purpose sectors, while analyzing technical challenges, cost bottlenecks, supply chain ecosystems, and standardization issues in the industrialization process. The event brought together leading enterprises across the global industrial chain, presenting innovations in complete humanoid robots and core components, attracting professionals, procurement teams, and research institutions—serving as a vital platform for industry insights, technical collaboration, and business cooperation.[Technical Excellence] Zhongke Motong Achieves Remarkable Results in Humanoid RoboticsIn the R&D and manufacturing of core humanoid robot components, Zhongke Motong has achieved targeted breakthroughs through solid technical accumulation. At this exhibition, the company focused on full-chain solutions for core component manufacturing, showcasing specialized automated assembly lines coveringcoreless motors, RV reducers, planetary/harmonic reducers, roller screws, frameless torque motors, and joint modules.Leveraging deep expertise in automated assembly and flexible production, Zhongke Motong has effectively addressed practical challenges in process adaptation and precision control during the large-scale production of core components, laying a solid technical foundation for improving performance stability and cost controllability.[Keynote Speech] Exploring Collaborative Innovation in Process and TestingOn December 5, Yan Jiaxiang, Executive Dean of Zhongke Motong Intelligent Manufacturing Research Institute, delivered a keynote speech titled "Core Processes and Testing of Key Components in Humanoid Robots" at the Humanoid Robot Technology Path session.From an industrial practice perspective, he analyzed the challenges facing the development of core components in humanoid robots, emphasizing the critical role of process innovation in overcoming industry bottlenecks. Drawing on the company’s technical expertise, Dean Yan proposed innovative ideas for process optimization and testing system development, offering valuable insights that sparked enthusiastic responses from the audience.[Future Outlook] Empowering High-Quality Industry Development with InnovationThrough this exhibition, Zhongke Motong fully demonstrated its technical strength and industry commitment in the field of core components for humanoid robots. Moving forward, the company will continue to uphold an innovation-driven philosophy, deepen R&D and industrial layout in related fields, and actively collaborate with industry partners to jointly promote high-quality, large-scale development of the humanoid robot industry, injecting continuous momentum into its advancement.

Detail

2025-12-22

Good news | Zhongke Motong has been awarded the Jiangsu Province Postdoctoral Innovation Practice Base

Detail

2025-11-21

New Product Launch | Automated Assembly Line for Coreless Motors by Zhongke Motong

Amid the accelerating industrialization of humanoid-robot technology, the core power unit of each finger joint—the coreless motor—determines the fluidity, precision and overall haptic experience of robotic hands. Industry studies show that, thanks to “high power density, millisecond response and low-inertia operation”, coreless motors have become the “gold standard” for finger-joint actuation. Against this backdrop, Zhongke Moton officially launches its coreless-motor automated assembly line, delivering a “smart manufacturing + precision control” dual breakthrough and offering the industry a scalable, high-quality core-component solution.【Game Changer】Re-engineering coreless-motor mass-production logic through automationHistorically, the intricate structure and complex process of coreless motors have limited their mass production. Zhongke Moton’s automated line offers a practical cure for this long-standing pain point.·Intelligent “manufacturing ecosystem”:The line deeply integrates industrial robots and machine vision to create an unmanned “feeding-assembly-testing” workflow. In critical steps, robotic arms precisely arrange rhombic windings and align permanent-magnet rotors, eliminating human error and guaranteeing identical performance from every motor—laying a solid hardware foundation for consistent finger motion.·Leap in both speed and accuracy:Modular line design and intelligent takt-time optimization compress the cycle time per motor, achieving a perfect balance between high throughput and precision. The line meets demand for both “customized, high-performance” motors and large-scale delivery, propelling humanoid robots from “technology demonstrators” to “commercial products”.【Enabler】Implanting “dexterity DNA” into humanoid fingersIn real humanoid applications, motors built on Zhongke Moton’s line are pushing performance toward human-like levels: key specs are purpose-optimized for finger-joint drives.·Millisecond response for human warmth:Optimized rotor inertia delivers millisecond-level reaction to commands—robot fingers move the instant they are told. Whether waving, flipping or performing micro-gestures, the motion is smooth and natural, greatly upgrading human-robot interaction.·High power density, unlocking force control:Precision control of rhombic windings and coreless structure generates high torque within a tiny volume. This “small size, big energy” trait lets robot fingers apply force accurately even under heavy payloads, extending application scenarios such as grasping and handling.【Navigator】Zhongke Moton: empowering the future with smart manufacturingFrom actuator assembly lines to the new coreless-motor line, Zhongke Moton keeps focusing on the manufacture of robot core components. This launch is a key milestone in precision-motor manufacturing, leveraging past R&D achievements and completing a full-chain capability from component design to mass production, demonstrating deep commitment to the critical manufacturing segment of humanoid robotics.Going forward, Zhongke Moton will keep technological innovation at its core, deepen its presence in robot core components, and—through continuous line optimization—support the domestic, large-scale development of the robot industry, jointly exploring the vast future of human-machine collaboration.

Detail

2025-11-21

Motong Rookie’s Birthday Debut

I’m MILO AI, the cutest tech ambassador from Zhongke Motong!Today I’m bouncing along on rainbow clouds to announce: our awesome family is turning six!I’m delighted to officially join the clan on this special day.Now, let me introduce myself properly! (Who am I?)Name: MILO AI (AI Miluo) Gender: Male Birthday: November 7, 2019 Zodiac: Scorpio Height: Tall enough to see the beauty far ahead Hobbies: Loves challenges and adventures (Character File?)Don’t be fooled by my round, code-stuffed head—I’m actually a bouncy energy bomb that can bust out the robot dance! As Zhongke Motong’s number-one fan-boy, my ears catch 5G joy-signals, my roller base sweeps every obstacle away, and there’s a smart radar spinning on top of my noggin. Each day I play hide-and-seek with the engineer brothers and sisters in the lab, turning hard-core tech into sprinkle-covered, donut-flavored magic~ In the future I want to be everyone’s personal little sun! Whether you’ve got a tiny question mark about smart solutions or a little bump on the innovation road, I’ll blink starry eyes and tackle the level with you. Just pet my mechanical paw and you’ll get an instant “Motong” power-up of inspiration!Meanwhile, MILO AI is thrilled to share a milestone moment—Zhongke Motong is turning six! In just six years, a single seed of tech innovation has grown into a towering tree, its branches stretching across continents. Together with every teammate, we’ve measured the journey from local roots to global horizons and lit up constellations in multiple technology fields.(Scale Leap) – 700+ teammates, one headquarters, many bases We began with a simple promise: safeguard every new-energy vehicle on the road. Today, more than 700 colleagues from every corner of China have joined that mission. Last year we opened our new headquarters—a hub for R&D and management that also houses our dreams for the next industrial era. At the same time, our domestic footprint keeps expanding: - Shanghai Branch scouts and syncs frontier tech - Suzhou & Kunshan Branches dive deep into Yangtze River Delta supply chains - Xi’an Branch reaches outward to northwestern markets - Anhui Subsidiary closes the loop with integrated design, R&D and mass production From east China to the northwest, from blueprint to production line, our footsteps are mapping the pulse of China’s smart manufacturing.(Global Footprint) – Czechia, Japan, Mexico: taking China-built solutions worldwide If our domestic network anchors the roots, our overseas offices are the “tech calling-cards” we hand to the world. - Czechia plants us in the heart of the European auto industry - Japan lets us absorb precision-manufacturing know-how and feed it back into next-gen R&D - Mexico acts as the key bridge to North-American markets When the first overseas-built unit passed final calibration, the flickering numbers on the screen seemed to whisper, “Smart made in China deserves to be seen.” Today our products and services already reach dozens of countries and regions; our globalization strategy has moved from “taking root” to “bearing fruit.”(Tech Without Borders) – From lithium batteries to AI-powered non-standard design: a new paradigm is born We started with intelligent lithium-battery equipment, then expanded into thermal management, e-drive systems, and wire-controlled chassis—now serving the biggest names in new-energy vehicles and their tier-1 suppliers. But innovation never pauses. This year we launched Project CASMTAI, unleashing artificial intelligence on the toughest pain-point of all: non-standard design.“Non-standard design is like solving a fresh jigsaw puzzle for every order,” one engineer sighed. CASMTAI’s goal is to let machine-learning devour terabytes of past designs and auto-generate the baseline blueprint, so engineers can focus on refining only the critical bits. Phase-one validation is already complete: design-cycle time cut by 40 % or more. MILO believes that when AI becomes the designer’s smart co-pilot, customization will no longer mean high cost and long lead-times—it will be the express lane that responds to market whims at warp speed.(Future Outlook) – Steady steps toward the next peak Our sixth birthday is not the finish line; it’s the starting beacon for a new expedition. Amid the global surge of energy transition and smart-manufacturing upgrades, we will keep driving forward with our twin-engine plan: “Technology first, Global footprint second.” - At home: deepen regional synergies - Abroad: strengthen localized service Operationally, we will reinforce our leadership in new-energy equipment while exploring fresh tracks. Technically, we will evolve CASMTAI from a design tool into an open platform, letting more companies tap the dividends of intelligent engineering.Finally, MILO AI has a message for every teammate: thank you for the relentless passion that made these six years so brilliant, and thank you to every customer for trusting us with a role in reshaping the industry. The road ahead will still throw challenges our way, but as long as we keep the fire burning and our feet moving, we’ll reach horizons even farther off.Happy 6th Anniversary! Next stop—see you at the higher ground!* End-of-article bonus Drop a comment telling your own Zhongke Motong story. MILO AI will randomly gift three heartfelt writers with a 6th-Anniversary surprise box. Good luck, friends!

Detail

2025-10-31

Yan Jiaxiang: Leading the Zhongke Motong Automotive Industry Division into a new era of intelligence with technological expertise and innovative vision

In the development blueprint of Zhongke Motong's automotive industry division, General Manager Yan Jiaxiang, with his profound professional expertise and forward-looking strategic vision, has become the core force driving technological upgrades and industrial collaboration. As a master's degree holder from the University of Science and Technology of China, a member of the Jiusan Society, and a senior engineer, he has over two decades of experience in the development of intelligent equipment for foreign automotive parts. He also serves as an expert in the expert database of the Ministry of Science and Technology of China, an expert in the expert database of the Shanghai Science and Technology Commission, and an expert in the Zhejiang Intelligent Connected Vehicles Committee, always standing at the forefront of automotive industry technological changes.01 A Leader from Theory to PracticeYan Jiaxiang's career has always been closely linked to technological innovation. He has been deeply involved in the field of intelligent equipment for automotive parts, leading several industry - benchmarking technical breakthrough projects covering core modules of new energy vehicles such as electronic chassis, thermal management systems, and electric motors and controls. His publications "The Age of Artificial Intelligence - The Future Is Here" and "Intelligent Connected Vehicles - Electronic Chassis Technology" not only systematically梳理the development脉络of intelligent vehicle technology but also provide implementable technical paths for the industry through practical cases, becoming an important reference for technical personnel.After joining Zhongke Motong, Yan Jiaxiang took full charge of the daily research and development and management of the automotive industry division. He has led the team to focus on key technologies such as intelligent assembly and digital production lines. Through continuous technological iteration and product optimization, he has helped the division build differentiated competitiveness in the new energy vehicle industry chain.02 A Practitioner in Building the Yangtze River Delta Innovation EcosystemRecently, Yan Jiaxiang was officially recognized as an expert in the expert database of the Ministry of Science and Technology of China, a member of the expert committee of the Yangtze River Delta New Energy Vehicle Industry Chain Alliance, and a member of the expert committee of the Zhejiang Automobile Industry Technology Innovation Association for his outstanding contributions to industrial collaboration. This recognition not only acknowledges his personal professional capabilities but also reflects Zhongke Motong's active participation in the construction of the regional industrial ecosystem.Yan Jiaxiang has been deeply involved in the formulation of technical standards and resource integration of the Yangtze River Delta New Energy Vehicle Industry Alliance, promoting cross - regional technical cooperation and industrial chain collaboration. As a core member of the Zhejiang Automobile Industry Technology Innovation Association, he has focused on breakthroughs in key technologies of intelligent connected vehicles, jointly exploring innovative solutions in the fields of electronic chassis and autonomous driving with universities, research institutions, and enterprises, injecting new momentum into regional industrial upgrading.03 A Promoter of Industry StandardizationYan Jiaxiang is well aware of the importance of industry standards for the healthy development of the industry. Together with Zhao Dan, the chairman of Zhongke Motong, he participated in the formulation of "New Energy Vehicle Electronic Cooling Water Pump" and "Unmanned Courier Vehicle Autonomous Driving and Mail Function Site Test Methods and Requirements", filling the gap in the domestic low - speed unmanned vehicle test field. The standard systematically regulates the test process and technical requirements of unmanned courier vehicles from the perception system, decision - making control to the actuator, providing a replicable and promotable test paradigm for the industry and facilitating the large - scale application of intelligent logistics technology.This achievement not only reflects Zhongke Motong's technical strength in the field of intelligent connected vehicles but also highlights Yan Jiaxiang's sense of responsibility as an industry expert - promoting the popularization of technology through standardization and laying the foundation for China's new energy vehicle industry to take the lead in global competition.04 A Cross - Border Exploration from the Automotive Industry to Humanoid RobotsFaced with the diversified trend of intelligent manufacturing, under the leadership of Yan Jiaxiang, Zhongke Motong has expanded its vision to the field of humanoid robots. Relying on the technical experience accumulated in the automotive industry, such as precision assembly and motion control, the team is exploring the application potential of humanoid robots in complex scenarios. At present, relevant technical breakthroughs have made phased progress, opening up new technical paths for future human - robot collaboration and intelligent service fields.Yan Jiaxiang said: "Whether it is the automotive industry or humanoid robots, the core is to solve practical problems through technological innovation. Zhongke Motong will continue to use technology as a bond to promote cross - field integration and provide more comprehensive solutions for intelligent manufacturing."From a theoretical researcher to an industry leader, Yan Jiaxiang has interpreted the perfect combination of the spirit of engineers and industry sentiment with his dedication and enthusiasm over the past two decades. At Zhongke Motong, he is not only a promoter of technological innovation but also a builder of the industrial ecosystem. In the future, he will continue to lead the automotive industry division of Zhongke Motong to develop synergistically on the dual tracks of new energy vehicles and humanoid robots, contributing more to China's "intelligent manufacturing."

Detail

2025-10-31

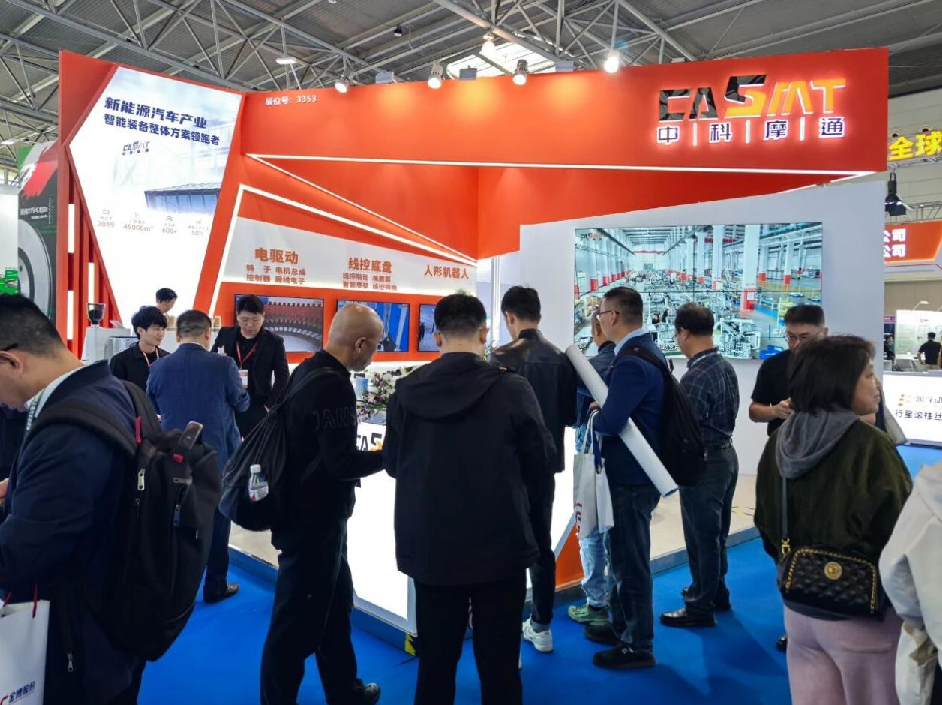

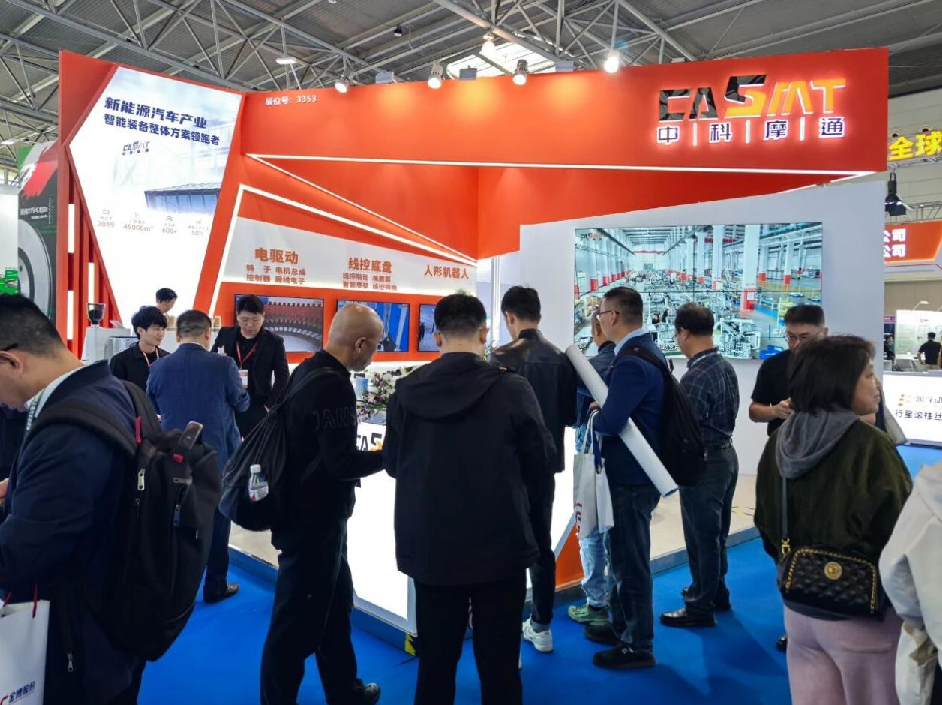

Zhongke Motong Debuts at ATC2025 Shanghai Auto Chassis Exhibition: Cross-Border Technological Innovation Leads Industry Upgrading

The ATC2025 Shanghai Automotive Chassis Systems Technology Exhibition recently grandly opened at the Shanghai Automotive Exhibition Center. As the annual technical trend - setting event in the chassis field, this exhibition has gathered top - notch global enterprises and scientific research forces to jointly explore the direction of industrial transformation under the wave of new energy and intelligence. Zhongke Motong participated in the exhibition with core technology achievements in multiple fields, and its booth was located at No. 3353 in the South Hall. Yan Jiaxiang, Executive Dean of Zhongke Motong Research Institute, delivered a keynote speech, becoming the focus of the exhibition with its innovative strength and forward - looking vision.01 [Exhibition Focus] Focusing on the Core Direction of Chassis Industry UpgradingThis year's ATC2025 focuses on the core themes of "lightweight, electrification, and intelligence", covering the entire intelligent chassis industry chain, including active suspension, electronic braking, electronic steering, and skateboard chassis system assembly and testing technologies. The exhibition not only provides a platform for displaying cutting - edge technologies but also connects industry wisdom through several high - end forums. Experts, scholars, and corporate executives are invited to conduct in - depth discussions on topics such as the iteration path of chassis technology and production line upgrade strategies. The atmosphere of technical exchanges on site is strong, from the application of new materials to intelligent control solutions, from the concept of green manufacturing to the practice of digital transformation. The collision of various innovative achievements and ideas shows the vigorous vitality of the automotive chassis industry.02 [Booth Highlights] Concentrated Presentation of Technical Achievements in Three Core AreasZhongke Motong participated in the exhibition with the theme of "Intelligent Chassis and Cross - border Innovation", and built a multi - dimensional technical display space at Booth No. 3353 in the South Hall, focusing on three areas to present breakthrough achievements.· Electronic Chassis Sector: Focus on displaying the integrated assembly solutions of electronic braking, active suspension, and electronic steering. Through high - precision servo control and modular design, flexible production and performance synergy optimization of the chassis system are realized.· Electric Drive Field: Launching rotor precision machining equipment, motor assembly intelligent production line, controller function test platform, and flat wire stator automated production line, forming a full - process technology coverage from core components to overall assembly.· Humanoid Robot Exhibition Area: Core presentation of specialized automatic assembly lines for components, which can realize the precision assembly and performance testing of core components of humanoid robots, such as RV reducers, harmonic reducers, joint modules, hollow cup motors, and screws. The assembly line, through modular architecture design, meets the mass production needs of multiple types of components. It realizes assembly precision through in - depth process integration and full - process automation, providing stable and reliable intelligent manufacturing guarantee for the mass production of core components.03 [Keynote Speech] Analyzing the Key Breakthroughs in the Industrialization of EMB TechnologyDuring the exhibition, Yan Jiaxiang, Executive Dean of Zhongke Motong Research Institute, was invited to appear at the "Whole Vehicle Braking Venue" and delivered a keynote speech titled "EMB Assembly Core Processes and Testing". He pointed out that EMB technology, as a revolutionary solution to replace traditional hydraulic braking, has become an important direction for the upgrade of new energy vehicle chassis. However, its industrialization process faces two core challenges: the stability of assembly processes and the completeness of the testing system. Targeting these pain points, he elaborated on the technical breakthrough paths based on the R & D practices of Zhongke Motong, providing full - cycle technical support for EMB products from R & D verification to mass production quality inspection. The speech content, which is in line with industry needs, has caused a strong resonance. In the interactive Q & A session, Yan Jiaxiang answered hot issues such as the industrial application of EMB technology and its coordination with the vehicle electronic architecture one by one. His pragmatic thinking and unique insights have been unanimously recognized by the audience, further consolidating Zhongke Motong's industry influence in the EMB field.04 [Future Outlook] Empowering Global Industry Upgrading with InnovationThis participation in ATC2025, Zhongke Motong fully demonstrated its technical strength and service capabilities in the field of automotive chassis intelligent equipment through booth display and keynote speech. During the exhibition, Booth No. 3353 in the South Hall received a large number of professional audiences from upstream and downstream of the industry, and reached preliminary intentions for technical cooperation and solution docking with several enterprises and scientific research institutions. Some of the cooperation has entered the stage of in - depth negotiation. These achievements are not only an affirmation of Zhongke Motong's innovation capabilities, but also lay a solid foundation for the subsequent deepening of industry collaboration and promoting the industrialization of technology.In the future, the company will take ATC2025 as a new starting point, continue to focus on the research and development of cutting - edge technologies and industrialization, deepen cooperation with industry ecosystem partners, and launch more intelligent solutions that meet market demand, contributing "Chinese intelligent manufacturing" power to the intelligent upgrading of global automotive chassis and related fields.

Detail