Release time:2023-08-24

From complex to simple thermal management integration module

On August 9th, BYD's 5th new energy vehicle officially went offline, becoming the world's first car company to achieve this milestone. This marks the arrival of a wave of new energy vehicles, and with the development of automobiles towards electrification and intelligence, the demand for energy management in automobiles is also increasing. The direct cooling and direct heating heat pump air conditioning heat management system is a new blue ocean in the field of new energy vehicles,With the rise of thermal management systems, the thermal management integration module, as a key functional component of the system, integrates relevant components,By accurately controlling the operation of various components through on-board computers, the safe, orderly, and efficient operation of each system is ensured, greatly improving the performance and reliability of the entire vehicle. At the same time, space and cost are saved, making the front cabin more standardized and aesthetically pleasing.

Local thermal management enterprises have demonstrated strong development potential

According to the current global new energy vehicle market pattern, the global automotive thermal management market space is expected to reach 120 billion yuan in 2025, and the domestic new energy passenger vehicle thermal management industry market space is expected to reach 75.7 billion yuan. With the emergence of more domestic automotive brands, providing more opportunities for domestic thermal management component suppliers to try will be conducive to the rapid growth of domestic thermal management system enterprises, thereby breaking the original supply chain system and entering a new period of automotive component growth. Its main advantages are manifested in the following aspects. First:Faster response from local supporting facilities,With the shortening of the domestic automotive development cycle, rapid response is crucial in the entire vehicle development cycle, and domestic domestic domestic enterprises can fully utilize this advantage; Secondly,cost advantage,Compared to the international market, China has lower labor costs and domestic equipment costs; Thirdly,Numerous new power brands in the early stages of enterprise development,It is easier to form industry chain stickiness and grow together.

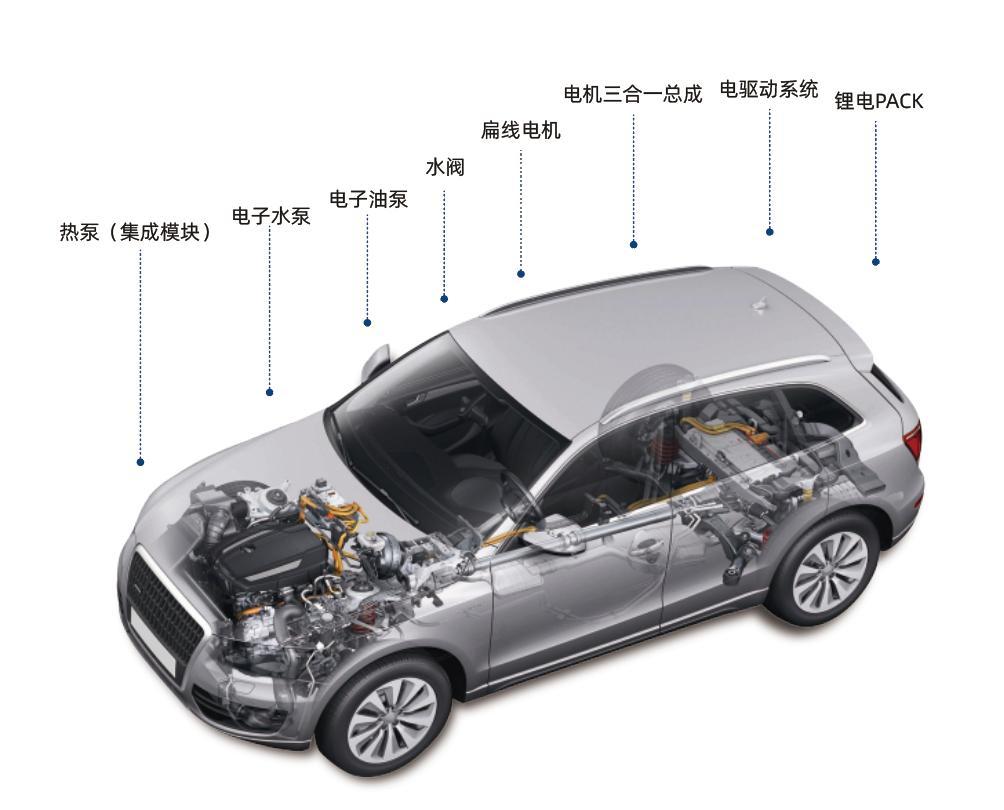

▲The picture is from the actual case of China Comoros

As a local car manufacturing enterprise, Nezha Motors adheres to the corporate mission of "breaking conventions, innovating technology to make travel more comfortable", with the concept of "building cars for the people", focusing on products and forward-looking technology, promoting the continuous evolution of electric vehicles, and leading the future trend of technological development. The integration of thermal management systems for new energy vehicles has taken its technological advantages, mainly by effectively achieving platformization, which is conducive to large-scale mass production and cost reduction, and can improve thermal management efficiency. Moreover, in terms of vehicle space, it can save more space and provide passengers with more usage functions. Nezha Motors has provided its own answer in promoting the continuous evolution of electric vehicles.

Zhongke Motong Assists in the Global Strategic Layout of Household Energy Storage Products

Zhongke Motong Helps Automobile Enterprises Grow and Strengthen

Zhongke Motong has launched strategic cooperation with Nezha Automobile this time, providing a fully automated intelligent production line with cutting-edge technology and predicting the future development direction of the industry, helping national automobile brands take off in the field of new energy vehicles.

▲The picture is from the actual plan of China Comoros

Thermal management module assembly automation production line

- Compatible with 3 products

- The overall production line beat is less than 65s

- OEE greater than 85%

The production line solves customers' high requirements for product efficiency and yield through the four core modules of the process.

Module 1: O-ring loading and damage detection

The O-ring is automatically fed through a vibrating disc, and the front and back of the O-ring on the small turntable are detected for damage.

Module 2: O-ring oiling and assembly

The O-ring is added to the component through mist injection to increase slip, and the O-ring is attached to the component through a dedicated clamp.

Module 3: Robotics and Visual Guidance

The machine grabs the components and visually guides them into the runner plate.

Module 4: Pressing and Tightening

Servo press compression components, force and displacement monitoring; The tightening gun is visually guided for tightening.

The assembly undergoes four steps of electrical testing, external leakage testing, internal leakage testing, and flow testing to ensure the qualified shipment of assembled products on the production line.

The manufacturing of new energy vehicles will become an important cornerstone in the field of intelligent manufacturing, driving the rapid development of high-end equipment manufacturing, information technology, artificial intelligence and other related fields. It is expected that in the future, the manufacturing of new energy vehicles will become an important industry in promoting the transformation and upgrading of the national economy and promoting intelligent manufacturing. We look forward to continuous breakthroughs and innovations in the direction of digitalization and intelligence with the new energy industry!

2025-03-24

Zhongke Motong recently announced that, relying on its technical accumulation in the field of intelligent manufacturing, it has successfully completed the research and development as well as industrial layout of the hub motor automated production line.This move marks a further expansion of Zhongke Motong's strategic map in the manufacturing field of core components for new energy vehicles (NEVs), injecting new momentum into the industry's technological innovation.Since its establishment, Zhongke Motong has always focused on the intelligent upgrade needs of the NEV industry chain. By deeply integrating automation, information technology, and intelligent technology, the company provides full-chain solutions from research and development to mass production for the industry. Previously, the company had established a leading position in niche fields such as thermal management, hairpin motors, linear control chassis, electric drive, intelligent driving, and energy storage batteries, winning market recognition with its rapid delivery capabilities and standardized production line design.Zhongke Motong - Intelligent Production WorkshopThe layout of the hub motor automated production line is an important measure by Zhongke Motong in response to industry technological changes.As a cutting-edge technology in the drive system of NEVs, hub motors are characterized by high integration, lightweight, and optimized energy efficiency. However, their large-scale production has long been constrained by complex processes and assembly precision requirements. Leveraging its core technical accumulation in motion control, vision inspection, and data traceability, Zhongke Motong is committed to overcoming the technological bottlenecks in hub motor production and promoting the transition of this technology from the laboratory to large-scale applications.The production line includes the following core equipment processes: rotor steel ring hot fitting/rotor magnet insertion/stator housing sealing detection/electronic module assembly/stator and rotor assembly/stator and shaft assembly/brake disc assembly, etc.In the development of the hub motor production line, Zhongke Motong continued its philosophy of "leading the market with technological innovation."By integrating flexible assembly processes and third-generation performance testing technologies, the company has built a digital solution covering the entire production process, achieving full automation and traceability from component processing to finished product assembly. In addition, Zhongke Motong introduced modular design concepts into the production line development, which will allow for rapid adaptation to different specifications of hub motor products in the future, helping customers meet diverse market demands.Zhongke Motong - Hub Motor Product SchematicThe popularization of hub motor technology will reshape the traditional automotive drive system and have a profound impact on chassis design, energy management, and vehicle lightweighting. Through the layout of intelligent production lines, Zhongke Motong not only reduces customers' production costs and technological barriers but also, with the "intelligent production + smart service" model, helps automakers accelerate technological iteration.Zhongke Motong has successfully developed hub motor assembly equipment and incorporated it into the core business sector of its NEV intelligent equipment, forming a synergistic effect with existing businesses such as thermal management and linear control chassis,creating a smart manufacturing ecosystem covering core components of new energy vehicles.Zhongke Motong's increased investment in the hub motor automated production line is not only another demonstration of its technical strength but also an accurate grasp of the trend of the NEV industry transformation. Under the drive of the "dual carbon" goals, with the deep integration of intelligent equipment and core components, Zhongke Motong is expected to lead a new round of industrial upgrading and provide key support for Chinese manufacturing to occupy a commanding position in global competition.2023-08-24

Global acceleration period for household energy storageIn the current global energy shortage and high overseas electricity and gas prices, household energy storage remains the first to break through. Under the trend of carbon neutrality, the industry is full of confidence in the household energy storage market, believing that it will become the fourth high-speed growth track in the new energy industry, following wind power, photovoltaic, and electric vehicles. Under the "dual carbon" goal, new energy represented by photovoltaic has experienced rapid growth under favorable policies. With the maturity of Energy storage and the decline of cost, family scenarios have gradually grown into an important field of new energy applications. Especially in overseas markets, with the continuous rise in household electricity prices, the economy of household energy storage is gradually becoming more prominent. In addition, government subsidies from various countries further promote its rapid popularization.In 2022, against the backdrop of weak global economic recovery and unstable international environment, the energy storage industry is facing opportunities for vigorous development, and the development momentum of household energy storage industry is particularly strong. Europe is the world's largest market for household energy storage applications. According to the outlook report on the European household energy storage market released by the European Photovoltaic Industry Association in December last year, the installed capacity of household energy storage in Europe is expected to reach 3.9GWh in 2022, a year-on-year increase of 71%; In a neutral scenario, the installed capacity in 2023 will reach 4.5GWh, with a year-on-year growth rate of 16%. In the long run, energy storage is a necessary prerequisite for supporting the growth of clean energy installations, so its potential is significant. Global energy storage installations are expected to continue to improve from 2023 to 2025, with a CAGR of 57% for new installations. The global new household energy storage market still maintains a high-speed growth trend. Domestic enterprises accelerating the expansion of household energy storage productsThe global energy transformation continues to advance, and energy storage has become an indispensable role in the future power system. Currently, the penetration rate of energy storage is still low, and there is huge room for growth. In the context of rapid growth in global energy storage demand, Chinese manufacturers of global energy storage cells are leading in shipping. Energy storage batteries are already a trillion level super track, and full development on this track requires both long-term planning for new energy and deep exploration of one's own track. Wanbang Digital Energy is the first in China to achieve the application of the entire system of optical storage charging and discharging, green electricity trading in home scenarios. In actual operation, the entire system experience is very good, and through practical work, it has opened up new sub tracks in the direction of home storage. Zhongke Motong Assists in the Global Strategic Layout of Household Energy Storage ProductsAs a strategic partner of Wanbang Digital Energy, Zhongke Motong has provided Wanbang with an intelligent production plan for the entire factory, helping Wanbang deepen its efforts in the field of new energy and expand globally. 1) The entire factory planning includes a complete set of automation solutions for home and commercial storage, including intelligent warehousing, AGV loading, module assembly welding, PACK assembly, AGV unloading, finished product testing, and outbound supply chain planning;2) 280AH square shell energy storage module PACK line, with a design beat of 12PPM+and an automation rate of more than 95% for the whole line, includes core processes such as automatic online, automatic glue pasting, automatic grouping, automatic CCS installation, automatic laser welding, automatic box entry, and automatic package offline;In the field of new energy, technological innovation is constantly occurring, and technological change is a constant challenge for production and research and development. Zhongke Motong has always been on the path of challenging itself, constantly innovating itself, technology, and products, keeping at the forefront of industrial technology, and providing strategic intelligent equipment to support future development for every customer.Founded in 2019, COMET is a national small giant enterprise specializing in the research and development of integrated solutions for intelligent equipment in the new energy industry. Relying on the strong scientific research and technology strength of Jiangsu Institute of Intelligence, Chinese Academy of Sciences, and Tianmu Lake Energy Storage Institute, Chinese Academy of Sciences, the company aims to provide automated, information-based, and intelligent production solutions for the new energy industry. The company's main products include automatic production lines for lithium battery energy storage modules, lithium battery energy storage PACK production lines, and lithium battery energy storage system assembly lines for power module PACK production lines. The company has successfully entered the new energy vehicle fields such as CATL, Honeycomb Energy, Keshida, Xingxing Charging, Anhui Tongsheng, Sichuan Avionics, Xinquan Co., Ltd., Kangshengjia Smart Energy, Wanbang Digital Energy and the head customers of energy storage system integration.2023-08-24

How complex is the manufacturing process in a car factory? Each day, BBAC delivers more than 30 million different components on its front wheel drive, rear wheel drive and powertrain platforms to its production processes at three plants. Each plant has 10 million parts in operation every day! Finally, delivering 430,000 finished vehicles a year requires an efficient and precise logistics system behind it, as well as seamless collaboration between supplier management systems. The logistics of the modern industrial system is a cosmic precision gear system. And the new energy vehicle industry model renewal rate is high, but also strengthen the high requirements of logistics operation, as the "operation center" of industrial automation, warehousing logistics is how to carry out seamless operation?The answer is the smart library +AGV two-pronged "artifact"! In recent years, with the gradual development of industrial automation and computer integrated manufacturing system technology, as well as the wide application of flexible manufacturing system and automated three-dimensional warehouse, AGV, as a means of connecting and adjusting discrete logistics management system, and the necessary automatic handling and loading means of its continuous operation, its application range and technical level have been rapidly developed. Take the automobile industry as an example. In recent years, many automated "black light factories" rely on not only automated equipment, but also the "God linkage" of intelligent libraries and AVG. The wide application of intelligent library and AGV in the automobile industry has driven the brand new reform of the domestic automobile production mode.As a manufacturer of customized non-standard equipment, flexible production line is the signature strength of Zhongke Motong. Smart libraries and AGVs are also key business strengths.New energy vehicles develop vigorously this year, and various models are constantly updated, which is a huge challenge for automobile manufacturers. Traditional automobile manufacturers have unified equipment production products, and the replacement production of various models is undoubtedly the biggest pain point for the vehicle model production switchover of automobile enterprises.Agvs show their skills in the production line of the automobile manufacturing industry, efficiently, accurately and flexibly complete the task of material handling. And can be composed of multiple AGVs flexible logistics handling system, handling route can be adjusted with the adjustment of the production process and timely adjustment, so that a production line can produce a variety of products, greatly improve the flexibility of production and enterprise competitiveness. In the working process of AGV transportation system, every step is a series of data and information communication and exchange process. There is a powerful database support in the background, which fully guarantees the AGV robot will not make mistakes in the operation process, can complete the task on time, and ensure the accuracy of data information.In addition to the greatly improved product compatibility, the assembly time of the production line is greatly reduced. AGV automatic driving liberates the labor force, which reduces assembly time by 20%, assembly failure by 39%, investment recovery time by 57%, and labor force by 15%. The "caching role" of the state library also enhances the efficient operation of AGVs to a greater extent. In the automobile enterprise manufacturing to achieve all-round improvement, improve the work efficiency, efficiency and effect.While improving the efficiency of production lines, enterprises are also concerned about the cost of production lines. Agvs have a short investment cycle and easy transformation. When the production layout changes, the cost of modification of AGV robots is low and only needs to change the track, and the upgrade cost is almost negligible. As a bank, the flexible and changeable library location can be fully and automatically upgraded according to the different changes of products and the coordination of data and hardware, which further realizes the in-depth development of long-term benefits of the enterprise.With the development of industrial informatization, the automobile industry has a rising demand for intelligent manufacturing equipment. Intelligent library and AGV robots can well adapt to the development trend of flexibility, agility, intelligence and information technology of modern automobile manufacturing technology, and achieve a qualitative leap in the production organization, information management and logistics technology of automobile assembly. Help enterprises to truly efficient intelligent production.